O社様のご要望 特殊バルブを小ロットかつ低コストで

フロムでは、当サイトで掲載している以外にもお客様のご要望にお応えする特注品の設計・開発を承っています。特殊な性能や高度な技術力を要求される製品も開発しておりますので、求める部品がないとお困りのメーカー様はご相談ください。

お客様の課題・悩み

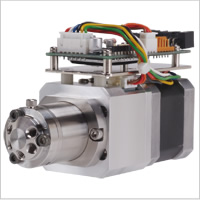

UHPLC(超高速液体クロマトグラフィー)用オートサンプラーに内蔵する自動バルブを必要としていたが、他社のメーカーでは価格が高額なうえに、弊社の製品仕様にあわせた設計要求にも応じてもらえませんでした。耐高圧設計のためバルブ内部のシール摩耗も早く、バルブの駆動回数が多いオートサンプラーでは製品の不具合が多発しておりました。

フロムへのご相談内容

「UHPLCに要求される高度な加工精度と、高い使用頻度に耐えることができる特殊なバルブを製作して欲しい」というご要望でした。

フロムからのご提案

新たな素材をシールの材料として採用し、耐久性の問題を大幅に改善したバルブの開発に成功し、ご提案しました。開発当初から顧客の製品仕様に合わせることを前提に開発を進めたため、お客様の製品仕様を変更せずに納品することができました。

完成品とお客様の声

ご提案通り、お客様の仕様に合わせた特殊なバルブを納品できました。お客様からは「バルブだけでなく、今の装置に変更を加えないという点にも配慮していただいて助かりました。他の部品もフロムさんにお任せしたいと思います」というお言葉を頂戴できました。

ご提案通り、お客様の仕様に合わせた特殊なバルブを納品できました。お客様からは「バルブだけでなく、今の装置に変更を加えないという点にも配慮していただいて助かりました。他の部品もフロムさんにお任せしたいと思います」というお言葉を頂戴できました。

製作期間

| ご相談から企画・提案まで | 2週間 |

|---|---|

| 企画・提案からサンプル製作まで | 6週間 |

| サンプル製作から本納品まで | 6週間 |

| 合計 | 14週間 |